You have no items in your shopping cart.

0item(s)

Cart

0 item(s)

View cart

You have no items in your shopping cart.

High Efficiency Particulate Air or HEPA for short. This type of filter is also known as high efficiency particulate arresting. Filters which meet the HEPA standard are used in many applications. This includes clean rooms, medical environments, manufacturing facilities, vehicles and homes.

HEPA filters remove up to 99.97% of particles equal to or larger than 0.3 microns.

HEPAs

HEPA filtration was invented in the 1940’s, developed by the military, to capture very tiny airborne radioactive contaminants. Today, seven decades later, HEPA filters are used in many commercial and various industrial applications.

A HEPA filter is a High Efficiency Particulate Air filter, designed to capture very fine particles, but they do not filter out gasses or odors. HEPA filters are required to remove 99.97% of airborne particles that are equal to, or greater than 0.3 microns in size. For comparison, a human hair is about 100 microns in diameter.

We humans spend the vast majority of our time in indoor settings. The U.S. Environmental Protection Agency (EPA) estimates that the indoor air that we breath can be up to five times more toxic than the outdoor air. We may be exposed to dust, pollen, pet dander and maybe even mould. At work, there may be viruses and bacteria in the air, as well as some chemical compounds, such as photocopy toner. We can’t always change the outdoor air around us, but air filters and particularly, HEPA filters can help keep our workplaces cleaner and safer.

The media used to create the arresting properties of a HEPA is typically made from randomly arranged, wet laid fiberglass fibres. The mechanical arresting natures of these fibres allows the media to capture extremely fine particles.

In most applications, pre-filters are recommended, to be used in front of the HEPA. Pre-filters help capture the larger particles in the air stream and they extend the service life of the HEPA filters. With proper maintenance and timely pre-filter change outs, some HEPA filters can last for years. HEPA filters are used in cleaning the air coming into a facility (like a hospital Operating Room) or exhausting hazardous air outdoors (asbestos abatement applications).

Other industries that require HEPA filtration may include, health and pharmaceutical facilities, many types of laboratories, electronic manufacturers, food and beverage processing plants, computer ventilation systems, and medical grow operations. HEPA filtration will help is ideal when the application require removal of pathogenic organisms and mold spore, or if you need to remove toxic dusts from the environment.

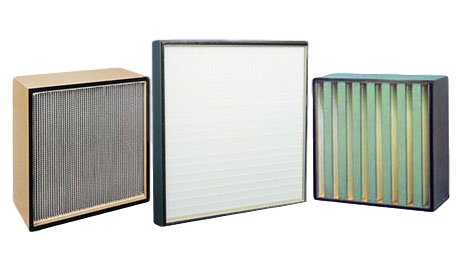

Just as all these industries are not alike, so too are HEPA filters. Some applications require different specifications, and United Filter can help you meet your specs. We can supply standard capacity volumes of air, or high capacity volumes. Standard models can be used up to 220F, and 100% relative humidity. Special high temperature HEPAs are available, and they operate up to 500F (260C).

United Filter can accommodate almost all HEPA requests. Our HEPA filters can be made with a galvanized or stainless metal frames or a wooden frame. We also can supply many custom sizes in 6 or 12” deep variations. No matter what specs you require, United Filter can help you with your choice.

Our HEPA filters are tested using the PAO (Polyalphaolefin) method, which has replaced the DOP (Dioctyl Phthalate), a known carcinogen. The POA is heated to its vapour point and then condensed back to a test aerosol of uniform particles of 0.3 microns, in size. Samples of air are taken in front of the HEPA and compared to samples taken after the filter. This newer method achieves accurate readings as low as one thousandth of one percent. The test results are marked on each filter.

For pricing call us at (905) 403-0160 or complete the quick form below and we will get back to you within one business day.

High Efficiency Particulate Air or HEPA for short. This type of filter is also known as high efficiency particulate arresting. Filters which meet the HEPA standard are used in many applications. This includes clean rooms, medical environments, manufacturing facilities, vehicles and homes.

HEPA filters remove up to 99.97% of particles equal to or larger than 0.3 microns.

HEPAs

HEPA filtration was invented in the 1940’s, developed by the military, to capture very tiny airborne radioactive contaminants. Today, seven decades later, HEPA filters are used in many commercial and various industrial applications.

A HEPA filter is a High Efficiency Particulate Air filter, designed to capture very fine particles, but they do not filter out gasses or odors. HEPA filters are required to remove 99.97% of airborne particles that are equal to, or greater than 0.3 microns in size. For comparison, a human hair is about 100 microns in diameter.

We humans spend the vast majority of our time in indoor settings. The U.S. Environmental Protection Agency (EPA) estimates that the indoor air that we breath can be up to five times more toxic than the outdoor air. We may be exposed to dust, pollen, pet dander and maybe even mould. At work, there may be viruses and bacteria in the air, as well as some chemical compounds, such as photocopy toner. We can’t always change the outdoor air around us, but air filters and particularly, HEPA filters can help keep our workplaces cleaner and safer.

The media used to create the arresting properties of a HEPA is typically made from randomly arranged, wet laid fiberglass fibres. The mechanical arresting natures of these fibres allows the media to capture extremely fine particles.

In most applications, pre-filters are recommended, to be used in front of the HEPA. Pre-filters help capture the larger particles in the air stream and they extend the service life of the HEPA filters. With proper maintenance and timely pre-filter change outs, some HEPA filters can last for years. HEPA filters are used in cleaning the air coming into a facility (like a hospital Operating Room) or exhausting hazardous air outdoors (asbestos abatement applications).

Other industries that require HEPA filtration may include, health and pharmaceutical facilities, many types of laboratories, electronic manufacturers, food and beverage processing plants, computer ventilation systems, and medical grow operations. HEPA filtration will help is ideal when the application require removal of pathogenic organisms and mold spore, or if you need to remove toxic dusts from the environment.

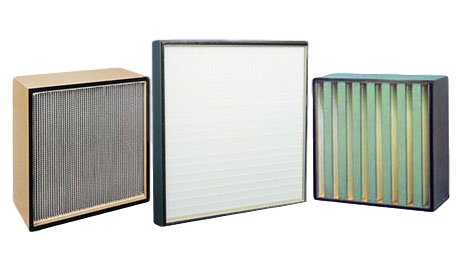

Just as all these industries are not alike, so too are HEPA filters. Some applications require different specifications, and United Filter can help you meet your specs. We can supply standard capacity volumes of air, or high capacity volumes. Standard models can be used up to 220F, and 100% relative humidity. Special high temperature HEPAs are available, and they operate up to 500F (260C).

United Filter can accommodate almost all HEPA requests. Our HEPA filters can be made with a galvanized or stainless metal frames or a wooden frame. We also can supply many custom sizes in 6 or 12” deep variations. No matter what specs you require, United Filter can help you with your choice.

Our HEPA filters are tested using the PAO (Polyalphaolefin) method, which has replaced the DOP (Dioctyl Phthalate), a known carcinogen. The POA is heated to its vapour point and then condensed back to a test aerosol of uniform particles of 0.3 microns, in size. Samples of air are taken in front of the HEPA and compared to samples taken after the filter. This newer method achieves accurate readings as low as one thousandth of one percent. The test results are marked on each filter.

For pricing call us at (905) 403-0160 or complete the quick form below and we will get back to you within one business day.