Vous avez pas d'articles dans votre panier.

Heating, Ventilation, and Air Conditioning (HVAC) systems are integral to maintaining indoor air quality and comfort in homes and commercial buildings. A crucial component of these systems is the HVAC filter, which not only helps in cleaning the air but also protects the HVAC system from dust and debris. In this article, we will explore the different sizes and types of HVAC filters, delve into the complexities associated with them, and discuss their various uses.

1. Types of HVAC Filters

HVAC filters come in various types, each designed to serve specific needs and environments. The type of filter chosen can have a significant impact on the system's efficiency, air quality, and maintenance needs.

-

Fiberglass Filters: These are the most common and inexpensive types of filters. Made from spun fiberglass, they are designed primarily to protect the HVAC system from large dust particles and debris rather than improving air quality. They have a low Minimum Efficiency Reporting Value (MERV) rating, typically between 1 and 4, making them suitable for systems where air quality is not a primary concern.

-

Pleated Filters: Made from cotton or polyester, pleated filters offer better filtration than fiberglass filters due to their larger surface area. The pleats allow for more dust and particles to be captured. They typically have a MERV rating between 5 and 13. These filters are a good balance between cost and performance, making them popular in residential and commercial settings.

-

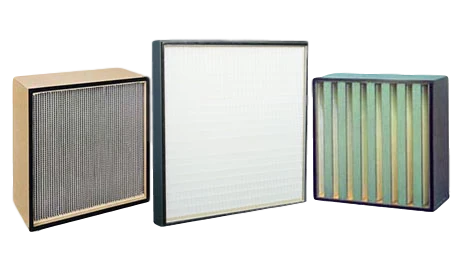

HEPA Filters: High-Efficiency Particulate Air (HEPA) filters are designed to remove at least 99.97% of airborne particles 0.3 microns or larger. With a MERV rating of 17 to 20, they are the gold standard for air filtration in environments where air quality is critical, such as hospitals and laboratories. However, their use in standard HVAC systems is limited due to the significant airflow resistance they create, which can strain the system.

-

Electrostatic Filters: These filters use an electric charge to attract and hold particles. They are available in both disposable and washable forms. The washable filters are more environmentally friendly and cost-effective over time but require regular maintenance. Their MERV ratings can vary widely, from 5 to 15, depending on the specific design.

-

Carbon Filters: Designed primarily to remove odors and volatile organic compounds (VOCs), carbon filters contain a layer of activated carbon that absorbs these particles. They are often used in combination with other filters to provide both particle and odor filtration. These filters are essential in environments where air quality and odor control are crucial, such as in kitchens or industrial settings.

2. Sizes of HVAC Filters

HVAC filters come in a variety of sizes, both in terms of dimensions and thickness. The size of the filter must match the specific HVAC unit to ensure proper fit and function.

-

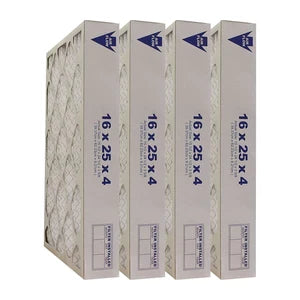

Standard Sizes: HVAC filters are available in standard sizes, such as 16x20x1, 20x25x1, and 16x25x1 inches, among others. These sizes are commonly used in residential systems and are readily available in most hardware stores.

-

Custom Sizes: For HVAC systems with unique requirements, custom-sized filters may be necessary. These can be ordered from manufacturers or specialized suppliers and are often used in commercial or industrial settings where standard sizes do not fit.

-

Thickness: Filter thickness can range from 1 inch to several inches, with thicker filters generally offering better filtration. Thicker filters (such as 4 or 5 inches) have more surface area, which allows them to capture more particles and last longer between replacements. However, not all HVAC systems are designed to accommodate thicker filters, so it's essential to check the manufacturer's specifications.

3. Complexities of HVAC Filters

While selecting an HVAC filter might seem straightforward, there are several complexities that need to be considered to ensure optimal performance and system longevity.

-

Airflow Resistance: One of the primary considerations when selecting an HVAC filter is the impact on airflow. Filters with higher MERV ratings typically offer better filtration but also create more resistance to airflow. If the airflow is too restricted, it can lead to reduced system efficiency, higher energy costs, and increased wear and tear on the HVAC components. Balancing filtration needs with airflow requirements is crucial.

-

Filter Replacement Frequency: The lifespan of an HVAC filter depends on several factors, including the type of filter, the environment, and the HVAC system's usage. For instance, a basic fiberglass filter might need to be replaced every 30 days, while a pleated filter could last up to 90 days or more. HEPA filters, used in specialized environments, may have different replacement schedules depending on their application. Regular replacement is essential to maintaining both air quality and system efficiency.

-

Compatibility with HVAC System: Not all filters are compatible with every HVAC system. For example, using a HEPA filter in a standard residential HVAC system could lead to significant airflow issues. It's essential to consult the HVAC system's specifications or a professional technician to ensure the chosen filter type and size are suitable for the system.

-

Environmental Considerations: The environment in which the HVAC system operates can also complicate filter selection. For example, in areas with high pollen counts, pet dander, or dust, a higher MERV-rated filter may be necessary to maintain indoor air quality. In industrial settings, filters may need to capture more substantial particles or handle higher volumes of air, necessitating more robust or specialized filters.

4. Uses of HVAC Filters

HVAC filters serve multiple purposes beyond just protecting the HVAC system. Their uses vary depending on the type of filter and the environment in which they are installed.

-

Improving Indoor Air Quality: The primary use of HVAC filters is to improve indoor air quality by removing dust, pollen, mold spores, and other airborne particles. This is particularly important for people with allergies, asthma, or other respiratory conditions. High-efficiency filters, such as HEPA filters, are crucial in environments where air quality is paramount.

-

Protecting the HVAC System: By trapping dust and debris, HVAC filters protect the system's components from damage. This helps prevent clogs in the ductwork and reduces wear and tear on the system's motor, blower, and other parts, ultimately extending the system's lifespan.

-

Energy Efficiency: A clean and properly functioning HVAC filter helps maintain efficient airflow, reducing the energy required to heat or cool the air. This can lead to lower energy bills and a reduced environmental footprint.

-

Odor Control: Carbon filters are particularly effective at removing odors from the air, making them valuable in kitchens, bathrooms, or any area where odors are a concern. They can also remove harmful VOCs, contributing to a healthier indoor environment.

-

Compliance with Health Standards: In commercial and industrial settings, HVAC filters are often used to comply with health and safety standards, such as those required in hospitals, laboratories, and food processing plants. These filters ensure that the air is free from contaminants that could pose a risk to human health or product integrity.

Conclusion

Choosing the right HVAC filter is essential for ensuring optimal air quality, protecting the HVAC system, and maintaining energy efficiency. Understanding the different types and sizes of filters, as well as the complexities involved in their selection and use, can help homeowners and facility managers make informed decisions that meet their specific needs. Whether it's a basic fiberglass filter for a home or a HEPA filter for a hospital, each type of filter plays a crucial role in keeping indoor environments comfortable and safe.

Heating, Ventilation, and Air Conditioning (HVAC) systems are integral to maintaining indoor air quality and comfort in homes and commercial buildings. A crucial component of these systems is the HVAC filter, which not only helps in cleaning the air but also protects the HVAC system from dust and debris. In this article, we will explore the different sizes and types of HVAC filters, delve into the complexities associated with them, and discuss their various uses.

1. Types of HVAC Filters

HVAC filters come in various types, each designed to serve specific needs and environments. The type of filter chosen can have a significant impact on the system's efficiency, air quality, and maintenance needs.

-

Fiberglass Filters: These are the most common and inexpensive types of filters. Made from spun fiberglass, they are designed primarily to protect the HVAC system from large dust particles and debris rather than improving air quality. They have a low Minimum Efficiency Reporting Value (MERV) rating, typically between 1 and 4, making them suitable for systems where air quality is not a primary concern.

-

Pleated Filters: Made from cotton or polyester, pleated filters offer better filtration than fiberglass filters due to their larger surface area. The pleats allow for more dust and particles to be captured. They typically have a MERV rating between 5 and 13. These filters are a good balance between cost and performance, making them popular in residential and commercial settings.

-

HEPA Filters: High-Efficiency Particulate Air (HEPA) filters are designed to remove at least 99.97% of airborne particles 0.3 microns or larger. With a MERV rating of 17 to 20, they are the gold standard for air filtration in environments where air quality is critical, such as hospitals and laboratories. However, their use in standard HVAC systems is limited due to the significant airflow resistance they create, which can strain the system.

-

Electrostatic Filters: These filters use an electric charge to attract and hold particles. They are available in both disposable and washable forms. The washable filters are more environmentally friendly and cost-effective over time but require regular maintenance. Their MERV ratings can vary widely, from 5 to 15, depending on the specific design.

-

Carbon Filters: Designed primarily to remove odors and volatile organic compounds (VOCs), carbon filters contain a layer of activated carbon that absorbs these particles. They are often used in combination with other filters to provide both particle and odor filtration. These filters are essential in environments where air quality and odor control are crucial, such as in kitchens or industrial settings.

2. Sizes of HVAC Filters

HVAC filters come in a variety of sizes, both in terms of dimensions and thickness. The size of the filter must match the specific HVAC unit to ensure proper fit and function.

-

Standard Sizes: HVAC filters are available in standard sizes, such as 16x20x1, 20x25x1, and 16x25x1 inches, among others. These sizes are commonly used in residential systems and are readily available in most hardware stores.

-

Custom Sizes: For HVAC systems with unique requirements, custom-sized filters may be necessary. These can be ordered from manufacturers or specialized suppliers and are often used in commercial or industrial settings where standard sizes do not fit.

-

Thickness: Filter thickness can range from 1 inch to several inches, with thicker filters generally offering better filtration. Thicker filters (such as 4 or 5 inches) have more surface area, which allows them to capture more particles and last longer between replacements. However, not all HVAC systems are designed to accommodate thicker filters, so it's essential to check the manufacturer's specifications.

3. Complexities of HVAC Filters

While selecting an HVAC filter might seem straightforward, there are several complexities that need to be considered to ensure optimal performance and system longevity.

-

Airflow Resistance: One of the primary considerations when selecting an HVAC filter is the impact on airflow. Filters with higher MERV ratings typically offer better filtration but also create more resistance to airflow. If the airflow is too restricted, it can lead to reduced system efficiency, higher energy costs, and increased wear and tear on the HVAC components. Balancing filtration needs with airflow requirements is crucial.

-

Filter Replacement Frequency: The lifespan of an HVAC filter depends on several factors, including the type of filter, the environment, and the HVAC system's usage. For instance, a basic fiberglass filter might need to be replaced every 30 days, while a pleated filter could last up to 90 days or more. HEPA filters, used in specialized environments, may have different replacement schedules depending on their application. Regular replacement is essential to maintaining both air quality and system efficiency.

-

Compatibility with HVAC System: Not all filters are compatible with every HVAC system. For example, using a HEPA filter in a standard residential HVAC system could lead to significant airflow issues. It's essential to consult the HVAC system's specifications or a professional technician to ensure the chosen filter type and size are suitable for the system.

-

Environmental Considerations: The environment in which the HVAC system operates can also complicate filter selection. For example, in areas with high pollen counts, pet dander, or dust, a higher MERV-rated filter may be necessary to maintain indoor air quality. In industrial settings, filters may need to capture more substantial particles or handle higher volumes of air, necessitating more robust or specialized filters.

4. Uses of HVAC Filters

HVAC filters serve multiple purposes beyond just protecting the HVAC system. Their uses vary depending on the type of filter and the environment in which they are installed.

-

Improving Indoor Air Quality: The primary use of HVAC filters is to improve indoor air quality by removing dust, pollen, mold spores, and other airborne particles. This is particularly important for people with allergies, asthma, or other respiratory conditions. High-efficiency filters, such as HEPA filters, are crucial in environments where air quality is paramount.

-

Protecting the HVAC System: By trapping dust and debris, HVAC filters protect the system's components from damage. This helps prevent clogs in the ductwork and reduces wear and tear on the system's motor, blower, and other parts, ultimately extending the system's lifespan.

-

Energy Efficiency: A clean and properly functioning HVAC filter helps maintain efficient airflow, reducing the energy required to heat or cool the air. This can lead to lower energy bills and a reduced environmental footprint.

-

Odor Control: Carbon filters are particularly effective at removing odors from the air, making them valuable in kitchens, bathrooms, or any area where odors are a concern. They can also remove harmful VOCs, contributing to a healthier indoor environment.

-

Compliance with Health Standards: In commercial and industrial settings, HVAC filters are often used to comply with health and safety standards, such as those required in hospitals, laboratories, and food processing plants. These filters ensure that the air is free from contaminants that could pose a risk to human health or product integrity.

Conclusion

Choosing the right HVAC filter is essential for ensuring optimal air quality, protecting the HVAC system, and maintaining energy efficiency. Understanding the different types and sizes of filters, as well as the complexities involved in their selection and use, can help homeowners and facility managers make informed decisions that meet their specific needs. Whether it's a basic fiberglass filter for a home or a HEPA filter for a hospital, each type of filter plays a crucial role in keeping indoor environments comfortable and safe.